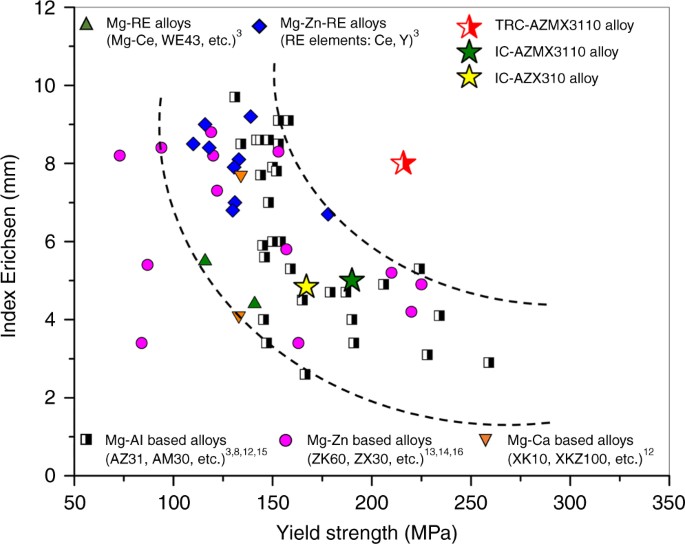

Although magnesium alloys, as the lightest structural alloys, offer significant potential for automotive applications, their applications remain limited due to their poor formability at room temperature. Since the strategies used for improving formability usually result in a degradation of strength, there are no high strength magnesium alloys showing good formability. Here we report an alloy design concept that can simultaneously provide high strength and good formability. Such designed alloy when subjected to an appropriate processing technique shows a combination of strength and formability that surpasses those of the existing magnesium alloys reported so far. The alloy design concept used in the present study is based on the utilization of alloying elements that can induce precipitation, as well as maximize the segregation of other texture-controlling alloying elements. Such developed alloy is expected to broaden the application of Mg alloy sheets, which are now starting to gain acceptance by automotive industries.

Magnesium

alloys, as the lightest structural alloys having a density about

one-fourth that of steels, offer significant potential for improving

energy efficiency of various transportation systems such as automobiles1,2.

Numerous R&D efforts in the last decade have led to the development

of various types of magnesium alloys having good combination of

strength and ductility3,4 and excellent corrosion resistance5.

Although there are many variants of magnesium alloys showing large

ductility, however, they usually show poor formability at room

temperature3,

hindering their widespread applications in automobiles. Poor

formability of magnesium alloys arises from several factors; development

of strong basal texture during rolling (thermomechanical treatment) and

limited number of available deformation modes due to magnesium having

hexagonal close-packed (hcp) structure6.

Although Mg alloys are readily formable at warm or high temperatures

despite their poor formability at room temperature, forming at warm or

high temperatures is quite energy intensive and inefficient. Therefore,

to make Mg alloys attractive for applications in automobiles, their

formability at room temperature should be improved. There have been

numerous attempts to improve formability of magnesium alloys and it has

been shown that the formability of Mg alloys can be improved by texture

randomization/weakening from the typical strong basal texture of

conventional Mg alloys, which is usually achieved by the modification of

thermomechanical processing7,8 and the addition of rare earth elements (REEs)9,10,11.

The randomized/weakened basal texture of REE-containing alloys is

certainly beneficial for formability, but also results in low strength.

Such inverse relationship between formability and strength is also

applicable to other non-REE containing Mg alloys3. Figure 1

shows the Index Erichsen (IE) value (which is an indication of stretch

formability; see Methods) as a function of yield strength of various Mg

alloys3,8,12,13,14,15,16. As shown in Fig. 1,

yield strength of Mg alloys having the IE values larger than 8 mm is

lower than ~160 MPa. However, as yield strength of Mg alloys increases

to 200 MPa, their IE values become lower than 6 mm, making them

non-formable at room temperature. It is apparent that the conventional

approaches that improve formability have adverse effects on strength or

vice versa. Therefore, new alloy design and processing concepts should

be utilized to develop high strength Mg alloys with good formability at

room temperature.

Fig. 1

In

this study, we report an alloy design concept that can simultaneously

provide high strength and good formability at room temperature. The

newly developed Mg-3Al-1Zn-1Mn-0.5Ca (wt.%) (AZMX3110) alloy using the

alloy design concept shows a much improved combination of formability

(IE value) and yield strength, namely IE value of 8 mm with yield

strength of 219 MPa, as compared to commercial as well as experimental

Mg alloys, as presented in Fig. 1.

Such improvement in the combination of formability and strength has

been realized by a judicious control of alloy chemistry and a selection

of appropriate process for such alloy chemistry. The composition of

AZMX3110 alloy is quite similar to that of the most familiar and

commonly used Mg-3Al-1Zn (AZ31) alloy. It is expected that such

composition of the developed alloy would lead to an early acceptance by

the users due to its similarity to AZ31 alloy.

Click Here to read full article

0 Comments